|

|

|

| SRP on Your Desktop |

|

With the MDX-40R 3D Milling Machine, you can quickly and easily create high-quality prototypes, parts and models right at your desktop. The MDX-40R allows industrial designers to perform a full range of subtractive rapid prototyping (SRP) applications in-house, eliminating the added time and security risks associated with outsourcing. It's a perfect tool for shortening the product development cycle and bringing complex product designs quickly to market.

|

High-Speed Performance And Generous Work Area

Featuring a powerful 100W brushless-motor spindle and 0.01mm/step software resolution, the MDX-40R quickly generates smooth-finished, beautiful results with precision every time. It accommodates a wide variety of low-priced materials including ABS, acrylic, chemical woods, plaster, styrene foam and wax. For optimum performance with a range of materials and cutters, the MDX-40R offers an adjustable spindle speed ranging from 4,500 to 15,000 rpm. Additionally, the MDX-40 features a generous work area of 305mm(X) x 305mm(Y) x 105mm(Z) (12"x 12"x 4.12", large enough for most small- to mid-size SRP applications

|

|

|

Easy To Operate

The MDX-40R is designed for easy operation with only four buttons: power, view, tool up and tool down. An on-screen operation panel makes using the MDX-40R even easier, allowing you to quickly select settings for both cutter movement and the cutting start location. Factory included origin sensors easily help identify the cutter tip and Z0 positions.

|

|

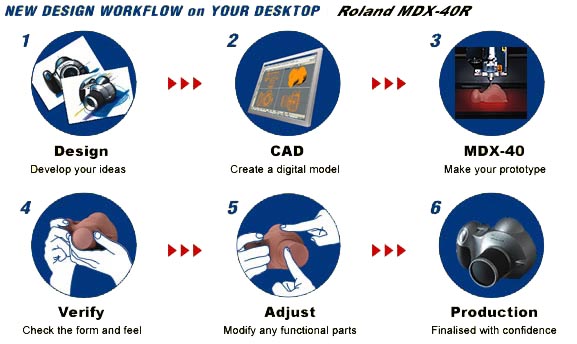

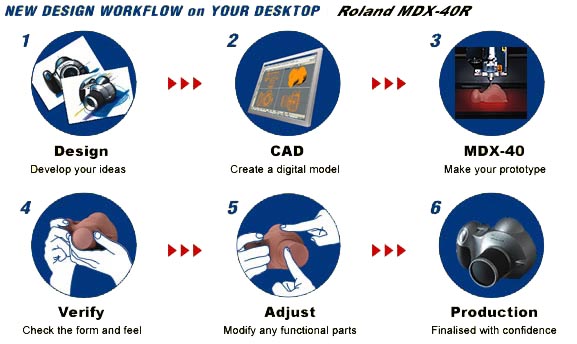

Designing with MDX-40R

|

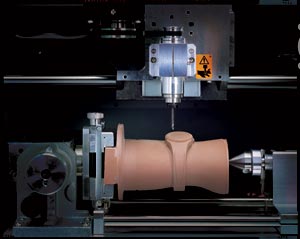

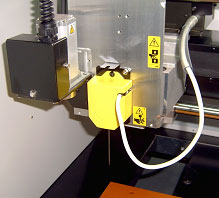

Optional Rotary Axis Unit and Scanning Sensor Unit

The MDX-40's Rotary Axis Unit*1 is designed for unattended 3D milling at any angle from 0 to 360 degrees. With the Rotary Axis Unit, you can easily and accurately mill a wide variety of two- and four-sided objects. In addition, an optional scanning sensor unit*2 can be easily installed. This unit comes with Dr. PICZA 3, full-featured scanning software that includes a wide variety of editing functions. With Dr. PICZA 3, scanning data can be exported in DXF, IGES or VRML formats, or as Point Cloud data (ASCII).

Rotary Axis Unit Scanning Sensor Unit

Clean, Quiet and Safe Work Environment

The MDX-40R features a compact footprint and fits easily on the desktop. A machine cover ensures a clean and quiet operation, making it ideal for office use. A new optional dust box collects cutting dust, further promoting a clean work area. An emergency stop switch ensures safe operation.

|

Supports Popular 3D CAD/CG Software and Includes Roland's CAM and CAM Simulation Software

|

|

The MDX-40R supports most popular 3D CAD/CG software packages and comes complete with Roland's own MODELA Player 4 CAM software and Virtual MODELA CAM simulation software. MODELA Player 4 controls an optional Rotary Axis Unit and supports industry standard file formats including STL, IGES*1 and DXF*2. This advanced, easy-to-use package allows you to confirm an object from various angles and produce a 3D rendering

With Virtual MODELA*3, you can accurately simulate finished shapes and estimate the production time for each job. This enables you to eliminate milling errors and to optimize both time and materials. The MDX-40R also includes Roland's 3D Engrave and Dr. Engrave engraving software. All Roland software packages are compatible with Windows® XP/2000/ME/98 and Window Vista®.

|

|

*1 IGES: compatible with IGES 5.2, surface only.

*2 DXF: compatible with 3D DXF of AutoCAD R12 format only.

*3 Virtual MODELA does not support the Rotary Axis Unit.

Spacification MDX-40R

|

Item

|

MDX-40R

|

| Acceptable material |

Resins such as chemical wood and modeling wax (metal not supported) |

| X, Y, and Z strokes |

305 (X) x 305 (Y) x 105 (Z) mm (12 (X) x 12 (Y) x 4-1/8 (Z) in.) |

| Distance from spindle tip to table |

Maximum 125 mm (4-15/16 in.) |

| Table size |

305 (W) x 305 (D) mm (12 (W) x 12 (D) in.) |

| Loadable workpiece weight |

4 kg (8.8 lb) |

| XYZ-axis motor |

Stepping motor |

| Feed rate |

XY-axis : 0.1 to 50 mm/sec. (0.0039 to 1.9 in./s), Z-axis : 0.1 to 30 mm/sec. (0.0039 to 1.1 in./s) |

| Software resolution |

0.01 mm/step (0.00039 in./step) |

| Mechanical resolution |

0.002 mm/step (0.0001 mm/step) |

| Spindle motor |

Brushless DC motor, Maximum 100 W |

| Spindle type |

Modeling spindle |

| Spindle rotation |

4500 to 15000 rpm |

| Tool chuck |

Collet |

| Interface |

USB connector, sensor connector, expansion connector |

| Power supply |

Voltage and frequency : AC100 to 240 ± 10 %, 50/60 Hz

Required power capacity : 2.1A

|

| Power consumption |

Approx. 210 W |

| Acoustic noise level |

No-load operation : 56 dB (A) or less, standby : 42 dB (A) or less (According to ISO7779) |

| Dimensions |

669 (W) x 760 (D) x 554 (H) mm (26-3/8 (W) x 29-15/16 (D) x 21-13/16 (H) in.) |

| Weight |

66 kg (146 lb) |

| Operation temperature |

5 to 40°C (41 to 104°F) |

| Operation humidity |

35 to 80 % (no condensation) |

| Included items |

Power cord, collet, sensor, hexagonal wrench, hexagonal screw drivers, spanners, Roland Software Package CD-ROM, MODELA Player4 CD-ROM, user's manual, Roland Software Package installation and setup guide, MODELA Player4 installation and setup guide |

|

|

|

บริษัทขอสงวนสิทธิ์ในการปรับปรุงรายละเอียดปลีกย่อยของสินค้า เช่นสี วัสดุที่ใช้ หรือราคาโดยไม่ต้องแจ้งให้ทราบล่วงหน้า โดยการปรับเปลี่ยนจะยึดเอาความต้องการของลูกค้าส่วนใหญ่ และ วัตถุดิบที่มีคุณภาพ มาใช้ทดแทนกัน เป็นที่ตั้ง สินค้าทั้งหมดได้รับการคุ้มครอง ภายใต้กฎหมายว่าด้วยลิขสิทธิ์ ห้ามมิให้บุคคล หรือ นิติบุคคลใดๆ ลอกเลียนแบบการออกแบบ ไม่ว่า ส่วนหนึ่งส่วนใด หรือทั้งหมด หากละเมิด ทางบริษัทจะดำเนินการที่กฎหมายบัญญัติเอาไว้สูงสุด

บริษัท ไอเดีย เมคเกอร์ เทคโนโลยี จำกัด (สำนักงานใหญ่)

1796-1800 ถ.สุขุมวิท ซ.ตรงข้ามบิ๊กซีจัมโบ้ ต.เทพารักษ์ อ.เมือง จ.สมุทรปราการ

ลงถนนกาญจนาภิเษก สู่ถนนสุขุมวิทเพียง 1 ก.ม

คลิกเพื่อดูแผนที่

Tel. 02-7550290-1 , 02-7578488-9 Hotline : 081-6298220 Fax. 02-7576980(Auto)

ในเวลาทำการ จันทร์-เสาร์ 08.30-17.30 น.